What Is An Articulating Trailer Coupler?

An articulating trailer coupler is a hitch mechanism that allows 360-degree rotation of a trailer-to-tow vehicle connection. It prevents the hitch ball from binding against the coupler.

Articulating (also called multi-axis) couplers are popular on off-road trailers. But as you’ll see, they are an excellent choice for on-road applications as well.

Articulating couplers exist to solve a common problem with conventional ball coupler: binding.

What’s the Problem with a Ball Coupler?

The standard coupler in the United States is a ball coupler.

Ball couplers deserve their own guidebook. There are three common ball sizes (1-7/8, 2, 2-5/16), A-frame and straight channel versions, sleeve-lock and trigger latch varieties, stamped versus forged construction, bolted vs weld-on, etc.

All ball couplers work much the same way, forming a partial ball-and-socket joint between the trailer and the tow vehicle. They work similarly to a human hip or shoulder joint.

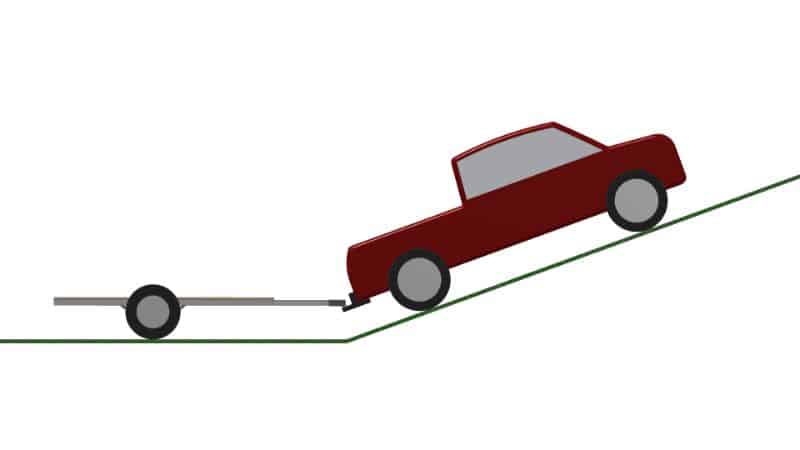

However, ball couplers do not allow for full articulation. It’s only a partial ball-and-socket joint! At steep angles, the body of the coupler will clash against the ball or drawbar. While details vary based on design, most ball couplers allow 15-25 degrees of vertical articulation (pitch).

That’s more than sufficient for on-road transportation. For reference, even a 20% road grade (like California’s Old Priest Grade Road) correlates to only 11.3 degrees. However, it may not suffice for 4×4 off-road trails.

What’s the Danger of a Binding Coupler?

- A steep vertical angle may cause the coupler mechanism to bind against the ball.

A bound coupler is incredibly dangerous. It fuses the joint together, transferring immense forces from trailer to tow vehicle (imagine jumping off a countertop with locked knees). A bound coupler can permanently damage the structure of the trailer, tow vehicle, or both.

- A steep vertical angle may cause the coupler to pop off the hitch ball.

The force of binding can overpower the coupler latching mechanism. If this happens, the coupler will pop off the ball. Then the only mechanism holding the trailer to the tow vehicle will be your safety chains (hopefully you crossed them into a basket!).

3 Types of Articulating Trailer Couplers

In the United States, there are three three popular types of articulating hitches.

Outside of the U.S., particularly in Australia, there are several other mechanisms made by companies such as AL-KO, ARK, and Cruisemaster. Australia uses a standard 50mm ball, which is usually compatible with an American 2” ball.

Pintle Hitch

The pintle hitch and lunette eye has long been a mainstay in off-road military applications. It’s a simple closed hook n’ eye coupling that’s robust, durable, and easy to maintain.

Technically, a pintle hitch doesn’t have unlimited articulation, and it has been known to bind. But this is rare.

Perhaps the larger complaint about a pintle hitch is the noise. Because the lunette eye must be slightly oversized, it pops and pings with every change of direction. That drives some drivers crazy! Plus, pintle hitches don’t tow well when unloaded; they will rattle continuously and accelerate metal-on-metal wear.

MAX Coupler

The MAX Coupler, designed by C U Offroad, is an SAE J684-certified articulating off-road coupler. Its patent-pending design uses an independent swivel pivot and sleeve hinge joints to achieve three axes of rotation. Polyurethane bushings absorb shock and maintain critical tolerances.

The MAX Coupler is rated for up to 6,000 lbs.

Like most articulating coupler designs, the MAX coupler replaces both the trailer- and tow-vehicle sides of your hitch mechanism.

Lock n’ Roll

The Lock n’ Roll Hitch, produced by Great Lakes Forge Co., is an SAE J684-certified articulating off-road coupler. It’s design uses a sleeved hinge joint paired with a swivel joint and a pivot joint to achieve three axes of rotation.

Due to its high-strength forged steel construction, the LNR hitch is rated for up to 11,000 lbs.

Like most articulating coupler designs, the Lock N Roll coupler replaces both the trailer- and tow-vehicle sides of your hitch mechanism.

(This author has used the Lock N Roll hitch and has been very impressed with its operation.)

How An Articulating Trailer Coupler Works

In the US, ball couplers are certified to the SAE J684 standard. Articulating couplers are expected to meet or exceed those same requirements.

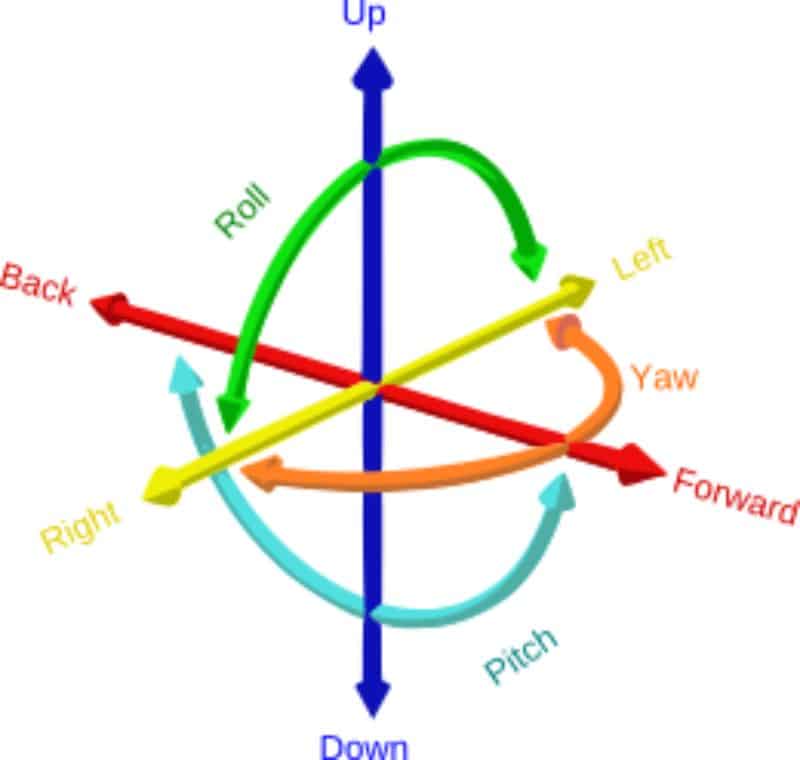

A simple joint has up to six degrees of freedom: translation forward/backward (surge), up/down (heave), left/right (sway), as well as rotation about the three axes (yaw, roll, and pitch.)

All couplers remove the freedom to translate in any direction. This is good! This keeps the trailer confidently connected to your tow vehicle.

All couplers also allow maximum yaw side-to-side. Generally, you will jackknife your vehicle before you max out the yaw capabilities of a coupler.

Where articulating couplers offer increased performance is with additional roll and pitch. And this is precisely where off-road vehicles need it most! Steep hills require additional pitch, and steep traverses require additional roll.

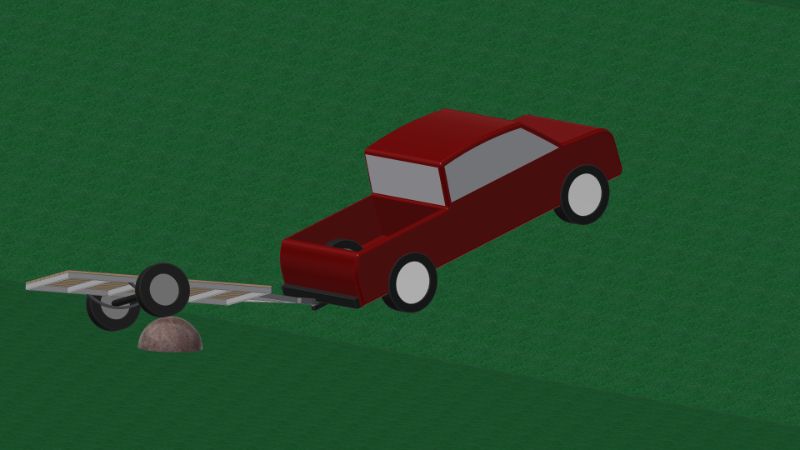

Here’s a picture of a common off-road situation where a trailer is being contorted along multiple axes of rotation. This can bind many ball couplers.

Are Articulating Couplers Good for On-Road Use?

Yes, they are! Articulating couplers offer three benefits for regular use:

A Noise-Free Connection

After a full year of testing, MotorTrend reported that the MAX 3-axis coupler maintained its noise-free performance. Compare that to the knee-buckling cracks and pops of a traditional ball coupler or pintle hitch!

Easy to Release

Ball couplers are notoriously difficult to release when bound. It can be all but impossible to lift the coupler off a ball after jackknifing too far. Articulating couplers will rarely bind and can be (usually) easily removed after reversing.

Increased Rollover Safety

Because an articulating off-road coupler allows 360-degrees of rotation, a trailer can completely roll over without taking down the tow vehicle with it!

GirlCamper’s Theresa Leppert shares a story how a wayward stabilizer jack caused her expedition trailer to roll over on a back road in Wisconsin. Because of her LNR hitch, the Jeep tow vehicle stayed upright even through the trailer flipped upside down. The trailer stayed in such good condition they simply righted the rig and towed it back home!

(A disclaimer: The author is not aware of any studies confirming the additional safety of an articulating coupler in the event of a collision or rollover incident. This evidence is purely anecdotal and may not be accurate.)

Is an Articulating Coupler Worth the Cost?

Depending on the make and model, it can cost $250 – $400 to outfit your trailer and tow vehicle with an articulating coupler from MAX or Lock N Roll.

An articulating coupler is not a requirement for landscaping trailers, ATV trailers, utility trailers, and other on-road trailers.

However, RV owners and 4×4 campers should seriously consider the benefits of a multi-axis coupler. Better to have it and not need it than need it and not have it!

Leave a Reply