Confession: I kinda have a thing for insulation. R-values excite me.

It comes with the brain type, I suppose. I’m an RV engineer by day, intrepid blogger by night. And I DESPISE – that’s all caps – many of the myths, misconceptions, and outright lies surrounding common types of RV insulation.

By the way, I wrote a condensed article on this topic that first appeared on Ashley Mann’s RV Inspiration. I encourage you to go check it out, especially if you’re considering renovating your RV (and to read more of Ashley’s excellent DIY RV content!)

STOP! – Mini Science Lesson

What Is R-Value?

R-value is a number that indicates how quickly material will transfer heat. The higher the R-value, the less heat the material will pass.

Materials with low R-values, like copper and aluminum, are called conductors. Materials with high R-values, like air and foam, are called insulators.

So your copper kitchen pans have a low R-value, but your foam mattress topper has a high R-value.

Here are some numbers for reference. These numbers are all for a material thickness of 1 inch!

- Wood: 1.0.

- Fiberglass batting: 2.5-3.2

- Styrofoam: 4-5.

- Aerogel (one of the world’s best insulators): 10. (Gadzooks!)

R-value increases with thickness. So a 2-inch thick piece of wood, for instance, would have an R-value of about 2.0.

Common Types of RV Insulation

Most RVs have three types of insulation.

- Foam: Also known as block foam or beadboard foam and available as either expanded or extruded polystyrene, foam is the mainstay of many RV walls and floors.

- Fiberglass: Available as loose-fill or batting, fiberglass is borrowed from the residential industry for its availability and cost. Quite frankly, I don’t like it, and I don’t think fiberglass belongs anywhere in an RV.

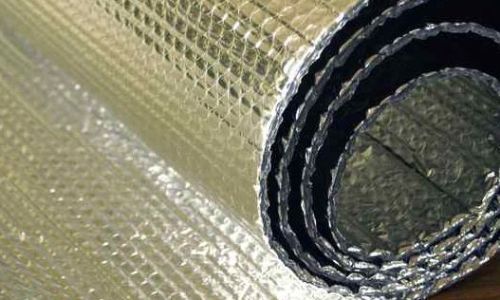

- Thermal reflective insulation (e.g., Reflectix): Also known as aluminum double bubble insulation, Reflectix is one of the least understood and least trustworthy types of insulation. It’s commonly used in RV ceilings (and often below the subfloor), but beware! – it might be worth nothing at all!

What Is Heat Transfer?

Hang with me! We’re almost done with the science lesson!

Understanding the modes of heat transfer is important for a serious RVer.

Because a 75-degree day in the sun can feel hotter than an 85-degree day in the shade.

Heat is transferred in three ways:

- Conduction: through objects touching

- Convection: when air or liquid flows around an object

- Radiation: through electromagnetic radiation in space

You can look up the technical definitions of these terms on your own time.

Let’s imagine a candle sitting on the kitchen table.

- Conduction: A drop of hot wax falls on your skin and burns you.

- Convection: You hold your hand over the candle flame, and the hot air burns you.

- Radiation: You enjoy the radiant warmth of the candle on your face.

1. MYTH: WYSIWYG

WYSIWYG is an acronym from the online design world: What You See Is What You Get.

Here’s an industry secret: There is no code or standard to determine assembly RV insulation R-value ratings.

So when Bob, your local RV salesperson, claims that “this here bad boy has R-11 walls and an R21 roof!” he’s just reciting what he memorized from the sales brochure.

Let me tell you a story, Reader.

I had a professor in college who held a propane torch to my face and blew the flame right at my face.

Well, almost. I was holding a thin, scrap piece of ceramic insulation from the nose cone of a NASA rocket. One side of the insulation was 3,000 degrees Fahrenheit and red-hot, but my face was cool and shielded.

Now, what if my professor had drilled a hole in the middle of that ceramic insulation? Well, I wouldn’t be writing this article, now would I? I’d be dead, with half my face melted off, and my professor would be in prison for manslaughter.

So let’s introduce the concept of whole-wall R-value.

A laminated RV sidewall, for instance, is actually made up of many layers: the gel-coated exterior fiberglass, the lauan substrate, the foam core, aluminum tubing, interior plywood, wallpaper facing, etc.

Foam is a good insulator. Aluminum is awful. So where the foam has been routed out to fit the aluminum tube, the wall loses R-value. In fact, those aluminum tubes act like little bridges, allowing massive amounts of heat to bypass the foam insulation!*

*That’s why we engineers call this phenomenon “thermal bridging.”

So when your WYSIWYG salesperson or brochure states that, “Our sidewalls have an R-value of 10!” that’s probably based on the idea that the wall has a 2-inch foam core.

The actual whole-wall R-value can be 10-50% less due to thermal bridging!

2. MYTH: RV Skirting Needs to be Insulated

Skirting is an interlocking wall of panels built around the base of your RV. The panels cover the space between your RV sidewalls and the ground.

Skirting is not so common on motorhomes and vans because these vehicles have insulated chassis bays. However, conventional travel trailers and 5th wheels have exposed underbellies which leak a ton of heat!

You can purchase commercial skirt kits for travel trailers and fifth-wheels, or you can make your own.

The myth states that the skirting panels must be insulated. For instance, they must be 1-inch or 2-inch thick block foam board.

But the truth is that it’s not about R-value; it’s all about airflow! Skirting stops cold air from flowing underneath your trailer floor, absorbing the heat, and blowing it away. It’s like a crawlspace. Neat, huh?

3. MYTH: Fiberglass Insulation Is (Somehow) Acceptable

Thankfully, most OEM RV manufacturers no longer use fiberglass batt or roll insulation in their sidewalls or ceilings.

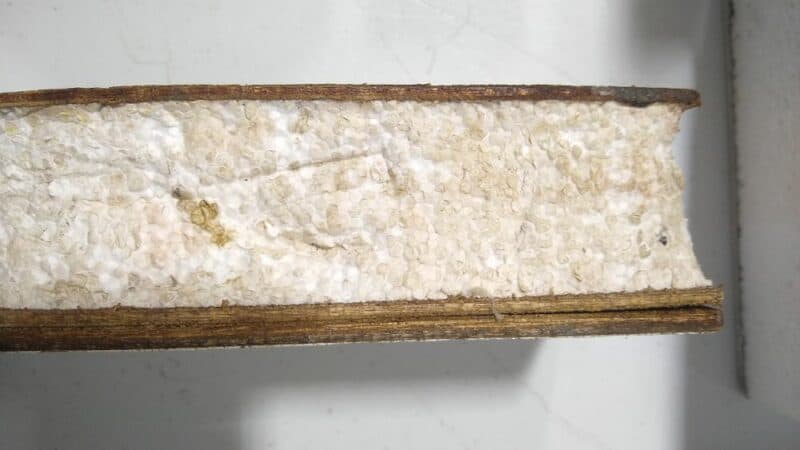

However, you’ll still find fiberglass batting in cheap stick n’ tin trailers.

It’s also a popular choice in the RV renovation world and DIY conversion vans.

Unfortunately, fiberglass is one of the worst types of insulation you can choose for an RV.

The shock and vibration of a traveling RV will cause the fiberglass to settle. This can leave empty “cold spots” where the insulation no longer fills the air gaps.

Virtually all RVs and vans will encounter significant interior condensation. Fiberglass absorbs moisture, which A) slashes it’s R-value and B) breeds mold inside your walls.

It’s not even a great insulator! Almost any other insulation product = rock wool, block foam, etc.- boasts higher R-values.

Many other insulators also stop air, which unfaced fiberglass can’t do.

I highly recommend leaving fiberglass on the shelf at Home Depot where it belongs.

- If you must use soft batting, use sheep’s wool. It’s hypoallergenic, easy to install, and mold-resistant.

- If you want to use semi-stiff batts, check out rock wool. It’s a much better insulator and noise reducer than fiberglass. Plus, it doesn’t absorb moisture!

- For flat construction, nothing beats foam board. Expanded polystyrene (EPS) is cheap, available and easily cut with hand tools. Plus, it has less environmental impact than XPS or polyiso foam board.

4. Myth: Double-Pane Windows Improve Your R-Value

There is a grain of truth in this myth.

Yes, at first, double-pane (aka thermopane) windows should reduce or eliminate interior condensation in your RV. Two panes of glass trap a layer of dead air space. This air space acts as an insulator and increases your window R-value. For that reason, they are a popular option in motorhomes and van conversions.

But there’s a reason they aren’t standard fare in most travel trailers and fifth-wheels.

For one, the effect of the increased R-value is minimal. Sure, it sounds impressive! Double pane windows are, truly, exponentially more energy-efficient than single-pane windows!

But RVs aren’t built with floor-to-ceiling glass. Unless you’re driving a luxury rig with a window always within arm’s reach, the impact on heat gain and loss in your RV will be minimal. The ratio of window-to-wall-area is just too small.

Even more importantly: Towable campers bounce around like a maraca. Over time, almost without fail, the seal or gasket surrounding the dead air space will break, allowing warm humid air to flood the inside of the window.

When this happens, the double-pane window condensates from the inside out. And it’s darn near impossible to fix. The windows must be professionally removed, cleaned and reinstalled, which costs almost as much as brand-new windows!

5. MYTH: Your RV Actually Has R-30/R-40/R-50 Insulation!

Any time you see an RV R-value above R-15, beware.

There is no enforced code or standard for RV manufacturers to test the “R-value” of an assembled unit! Although conscientious manufacturers will run testing (many have drive-in refrigerators) to justify their results.

When a manufacturer claims anything in excess of R15, it’s almost always a combination of reflective foil insulation and some other insulation.

Now, I don’t have time to cover the “Reflectix racket” in great depth. Simply put, reflective foil only acts as a radiant heat shield. It’s useless as a conductive insulator. If you put a layer of ¼-inch Reflectix foil between two pieces of plywood, guess what the R-value is? About 0.3! That’s almost nothin’!

Never, in all my life, have I seen Reflectix installed in an RV in such a way that it would actually warrant an R30 or R40 rating. Plus, don’t get caught up in those sky-high numbers anyway. Once you exceed a whole-wall R-value of R10, you’re ready for cold-weather camping.

6. MYTH: Use Window Covers in Winter

There is a grain of truth in this myth.

I actually highly recommend DIY reflective covers. They do a great job at reducing solar heat gain! If you’re camping in warm, sunny weather, they’re a great mod for your RV. But in winter, they just reflect away the heat you want to capture inside your RV!

To understand this, let’s look at how Reflectix insulates. The block foam in your walls, for comparison, insulates through conduction. Heat can’t easily pass through the material itself!

On the other hand, conductive heat can pass through the aluminized foil very easily! It’s aluminum, the same material used for kitchen pots and pans precisely because it distributes heat so quickly!

The magic happens because of reflection. As sunlight passes through the window, part of it is reflected by the window, part of it is absorbed into the glass and creates heat, and part of it passes through.

The part that passes through heats the reflective foil, bounces off, and passes through the window the other way. Again, part is transmitted, part absorbed, part reflected … and the cycle continues.

Here’s why you should know this.

- In the summer, covered windows will get stupidly hot. It’s because of all that waste heat generated through absorption. I’ve literally burned and blistered my thumb from touching a glass window covered with Reflectix. I’ve even heard of windows shattering from the heat!

- The covers aren’t as effective at night or during winter. They aren’t worthless, but RVs lose heat at night through conduction and convection, not so much radiation.

There are much better options for insulating RV windows for winter! Check out some ideas here at RVInspiration.com.

Leave a Reply