What are RV cabinets made from? Does this question keep you up at night, like me?

Most RV cabinets look the same. They look something like this (see below). What’s really going on behind that gray-gray-gray facade?

Fair warning: I sling around a lot of woodshop lingo in this article. I’m assuming you have a fairly high level of knowledge about woodworking. If you don’t know a thing about wood other than that it burns and it comes from trees, then here’s the short answer:

Short Answer: Most RVs don’t build the furniture using solid hardwood or plywood. Most manufacturers use a combination of lauan plywood and vinyl-wrapped particle board, which are lesser-grade materials.

I’m not suggesting you avoid particle board entirely. I’m simply suggesting you ask yourself whether it’s a good fit. If you only plan to use your RV a handful of times a year, then maybe you don’t want to pay the premium for veneer plywood and hardwood – and that’s fine!

(Skip to the end of the article to learn a few other reasons why furniture construction matters.)

How Is RV Furniture Built?

Note: In this post, I’ll be talking about the carcass and frame construction – not the drawers, fronts, drawer boxes, etc. That’s a whole other conversation!

RV cabinets aren’t like your house cabinets – and this is a good thing. Otherwise, your cabinets would weigh so much you’d never get more than a mile down the road!

By and large, RV manufacturers use framed cabinet construction, also called “American style.” This is in contrast to frameless construction, also called “European style,” which has rapidly become the new standard for residential home construction.

(To be honest, many RV cabinets don’t even deserve the term “framed cabinet construction.” Lots of built-ins are only 2- or 3-sided boxes built with 2x2s, 1/8″ paneling, and a few dozen staples!)

The reasons why RV manufacturers prefer framed construction are too numerous to list here. I’ll just mention the top three reasons:

- It’s strong. The face frame holds its shape well, even under stress. A cabinet doesn’t need a full four-sided box to hold its shape. In an RV, this usually means you can use less material and save weight (and money).

- It’s easy to build. You can get away with pocket screws or bridge staples, whereas frameless construction sometimes requires specialty fasteners (like Confirmats).

- It’s affordable. With framed construction, you can use simple overlay hinges. Frameless cabinets usually require much more complicated multi-point mortise hinges, especially in tight spaces.

Some furniture pieces (bottom, sides, backers) are cut out on a CNC router. Simple false walls and backers may be cut out on a panel saw or table saw. Structural walls are often stick-built with 2x2s using jigs, glue and staples (or screws).

An assembly line team assembles the furniture and places the cabinets on the RV floor, usually before the walls are mounted. In this way, RVs are built “inside-out.”

In many cases, such as in slide-outs or bulkheads, cabinets may be considered semi-structural members. In other words, the engineer may be counting on the furniture to help the RV keep its shape, even when stressed.

You can watch an RV Factory Tour video to get a sense of how cabinets are constructed. Skip to 15:00 on the video below to see furniture mounted on the floor before the walls are installed.

How Can You Tell Whether RV Furniture Is Good Quality?

So maybe you don’t know (or want to know) that much about wood types. How can you tell whether RV furniture is high-quality or not?

Here are a few litmus tests I recommend:

- Press down on the shelves. A good shelf should be thick enough that it feels solid and doesn’t bend when you push it.

- Look underneath the bed frame. Is the bed frame made from aluminum (good) or 2×2’s (so-so)? If made with wood, are the joints securely glued and stapled or screwed? Or is there only one little bridge staple in each joint?

- Inspect the hardware. Are the doors mounted with cheap wing hinges and secured with cheap roller catches? Or are they mounted with soft-close hinges?

- Push on the carcass sides. If the cabinet sidewalls are made from flexible, weak 1/8” plywood or particle board, they won’t survive long-term use.

If you’re shopping at an RV show, I have even more tips for judging RV construction quality!

What Materials Are RV Cabinets Made Of?

That depends on the manufacturer, of course. Here are some common materials:

Again, I’ll be talking about the carcass and frame construction – not the drawers, fronts, drawer boxes, etc. That’s a whole other conversation!

Particle Board

Not to be confused with OSB, which looks similar but has significantly better structural ratings, particle board is basically wood chips and glue.

It’s not great stuff. It’s heavy, it doesn’t hold screws well, and it expands like a pufferfish when it gets wet.

Unfortunately, it’s so cheap that many RV manufacturers can’t stay away from it. It’s almost never used as-is; it’ll be wrapped in vinyl or laminated to melamine.

You’ll often see ⅜” or ½” thick wrapped particle board used for cabinet sides and bottoms; you’ll see ¾” or ⅝” thick wrapped particle board used for face frames and sometimes even countertops.

Melamine

What most people call a “melamine” panel is actually a laminated panel with a particle board core and a melamine surface.

Melamine is actually a remarkable material used for sheet goods, adhesives, utensils, bowls, and many other products. But it’s typically laminated to particle board, which isn’t so great.

The saving grace of particle board is that it stays flat and doesn’t expand much in humidity (unlike plywood). That’s why melamine manufacturers often use it – because the expansion rates are similar.

While you can find melamine laminated to some other substrates, like plywood or MDF, I don’t think is common in the RV industry.

Melamine can last for decades. Its Achilles Heel is the corners, where water can get in. If you can keep water out, melamine will last a long, long time.

Fiberboard (MDF/HDF)

MDF is Medium Density Fiberboard. A close cousin is HDF, which is High-Density Fiberboard. It’s similar to particle board, but instead of being made with wood chips and glue, it’s made from sawdust and glue.

It’s denser and heavier than particle board, though. But in most other respects, it’s a superior product. A lot of premium residential cabinet builders actually insist on using wood veneer laminated to a treated MDF core, because it won’t bend or bow like plywood will.

You’ll see MDF used as the substrate on wrapped HDPL countertops. It’s not typically used in carcasses or frames; again, that’s where particle board still reigns supreme.

Plywood

Let’s talk about your Grandpa’s favorite material, the one he’s been hoarding in his garage for 32 years: plywood.

There are a bazillion types of plywood. No need to get into the weeds. In the RV industry, you’ll see four types:

- CD, BC Construction plywood: This is your typical construction-grade plywood. It’s kinda ugly, and so you’ll only see it used underneath beds, dinette seats, and that sort of thing. It’s made from domestic softwoods.

- Furniture-grade hardwood plywood: This is your typical furniture-grade plywood, usually graded AA, AB, or BB. It usually has a finished hardwood veneer (maple, cherry, walnut) and a softwood veneer core. You don’t typically see other cores (MDF, combination, or lumber core), although I’m sure someone out there uses it. Plywood is a rarity in most RVs! Premium builders will use it for general cabinet body construction.

- Baltic Birch plywood: This is good furniture-grade stuff, commonly used for drawer boxes. It’s typically graded BB. Most of the stuff comes from Russia, although other companies have taken note and are making similar stuff. Unlike conventional plywood, each ply and veneer is the same thickness. It’s attractive, but knots are removed and filled in by football-shaped patches. Mostly used for drawer boxes, but it’s also popular in most teardrops and micro campers.

- Poplar plywood: This goes by many trade names, like Lite Ply or Garnica. It’s usually made from 100% Italian or Spanish poplar, which is grown in giant European plantations. You’ll only see this stuff in premium campers: It costs 2x as much (and weighs 40% less) compared to regular A-B or B-B furniture-grade plywood. It’s often used in lightweight construction for cabinet carcasses to save weight.

- Luan plywood: Many lightweight cabinets are built with 1/8″, 3/16″, or 1/4″ luan plywood stapled to a pine wood frame. This is a common technique for overhead cabinet partition walls.

DRV Luxury Suites is an example of an RV manufacturer that uses real plywood and hardwood in their furniture construction:

Here’s the kicker, though: Plywood is expensive. On most affordable RVs, there’s almost no plywood … it’s all particle board. That includes the cabinet sides, floors, backs, and even face frames.

If you’re unsure, look at the back. You can often see a seam where the vinyl meets. Or look at the joints. Particle board frames are usually assembled with bridging staples; hardwood frames use pocket screws or tenons. It’s a dead giveaway. Nobody pays the premium for hardwood frames without also upgrading from staples.

Solid Hardwood

As I said, this post is about cabinetry box construction, not face frames. But here’s a brief tangent:

Solid hardwood is an endangered species in the RV ecosystem. It’s expensive to buy and even worse to produce: You have to run it through a planer, a joiner, a saw, a belt sander, and the spray booth.

But … there are manufacturers that build their face frames with solid hardwood frames. Properly taken care of, these frames will outlast you. Hard maple, walnut, red oak, hickory, and cherry are popular options.

Solid hardwood frames are usually assembled with pocket screws and wood glue or loose tenon joints. Both are excellent joinery techniques. Other types of face frame materials include vinyl-wrapped particleboard and wrapped lumber-core plywood, both of which are far, far more popular.

Lumber-Core

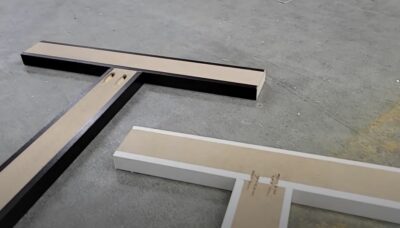

Most RV cabinet face frames are NOT made from hardwood. Instead, they are made from some kind of engineered “wood” product wrapped in vinyl wallpapering, like you can see in the picture above.

In some cases, the core of the frame rail or stile is just MDF or particle board. But in many cases, it’s a unique product called lumber-core, which is a double-decker sandwich of MDF, lumber, and MDF. The outside is MDF for a smooth skin that’s easy to wrap vinyl around; the middle is lumber (usually pine), so it can hold screws or staples.

What’s the Big Deal About Amish-Made Furniture?

One last thing to get off my chest: A lot of RV manufacturers like to crow about “Amish-made furniture.” Now, I like the Amish as much as anybody, but don’t pay this marketing much mind.

Elkhart, Indiana is smack-dab in the middle of Amish country, you see. There are over 23,000 Amish residents in Elkhart and LaGrange counties – everybody has somebody Amish working for them! And they use staple guns and impact drivers, same as everybody else. “Amish craftsmanship” plays very little part in how RVs are made.

Why You Should Care About RV Furniture Construction

So, here are the five reasons you should care about RV furniture construction:

- Water resilience. Plywood and hardwood don’t fall apart when exposed to water. Plywood will stain, but it (usually) stays intact.

- Weight. Plywood and hardwood generally weigh less than particle board by 15-40%.

- Cost. Wrapped particle board costs a lot, lot less than real wood!

- Air quality. If you’re sensitive to VOCs, the glues used in particle board and MDF can be very aggravating. Solid wood still off-gases due to the finishing, but it’s less.

- Durability. Real wood can be refinished; wrapped particle board cannot. When the vinyl or melamine fades, scratches or peels, that’s the end of the road.

I’m not anti-particle board. It has its place, absolutely. And there are many 15-year-old RVs with vinyl-wrapped particle board furniture that are still going strong. And if you don’t like how it looks, yes, you can even paint it.

Don’t walk away from an RV just because it has particle board furniture. But if premium craftsmanship and best-of-class longevity is important to you, ask your RV salesperson, “Where are the RVs with real wood furniture?” He’ll be happy to show you. They cost twice as much, and he’ll make a nice commission!

Leave a Reply