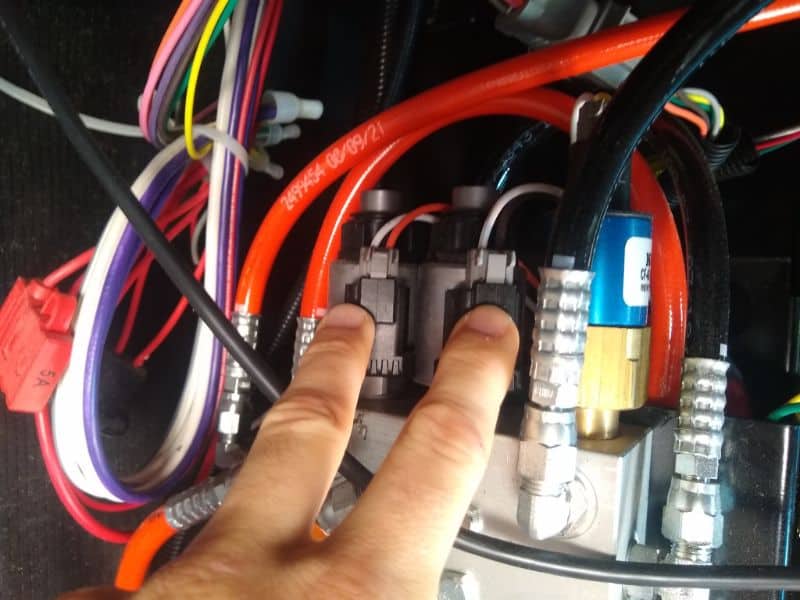

Many larger RVs and motorhomes use a pressurized hydraulic fluid system to move slide-outs, leveling jacks, and landing gear. They are relatively simple hydraulic systems. Most have a simple displacement pump and gearbox transmission, a machined manifold with solenoid-activated flow control valves, some safety switches, and a little PCB brain.

Note: As an RV engineer/tech, I am a jack-of-all-technical-trades. (It’s part of the job description.) I do some HVAC/R, some mechanics of materials, some thermodynamics, some plumbing, some electrical, some hydraulics, etc. But I wouldn’t call myself a Subject Matter Expert on hydraulics, so I’ll do my best to use accurate language.

The hydraulic fluid does all the work. The pump provides the pressure, but the fluid is what actually moves everything. Automatic transmission fluid (ATF) is a commonly recommended hydraulic fluid. In fact, I keep a gallon of Dexron III in my service vehicle.

Why Is My Hydraulic Fluid Frothy or Foamy?

If you’re hearing a particularly loud, whiny hum or grainy, rocky rumble while operating your hydraulic system, you should visually inspect your hydraulic fluid. It’s located in the main reservoir. This is usually a white plastic tank attached to the motorized pump unit. Retract all your hydraulic actuators, unscrew the breather cap on the reservoir, grab a flashlight, and peek inside. See any frothy, milky, or bubbly fluid? That’s a sign that air has invaded your hydraulic system.

Why Is There Air Inside My RV’s Loud Hydraulic Pump?

Air can get trapped inside hydraulic fluid, you see. Well, actually, you can’t see, because it’s often invisible. The foam you can see is just a small part of all the air in the system.

- Dissolved air is gas incorporated into the hydraulic oil as a solution. Some dissolved air is naturally present in all hydraulic fluid. Excessive dissolved air can cause cavitation, which kills pumps. Fun fact: Dissolved air, because it’s in solution, does NOT significantly change the volume of the hydraulic fluid.

- Entrained air is very small air bubbles, usually less than 1mm in diameter. Entrained air is evenly dispersed throughout the fluid. It causes lots of problems, mostly with the pump.

- Free air is large air bubbles, greater than 1mm in diameter. These bubbles or pockets of gas can get quite large and obnoxious. In plumbing systems, they can cause vapor lock or poor system response. In hydraulic systems, they are usually easily “burped” or “bled” by cycling the system a handful of times to its limits.

- Foam is air pockets on the surface of a fluid held together by surface tension. Foam is more symptom than syndrome. Foam can be generated by agitated entrained air, aeration from turbulence, or other causes. Foam itself isn’t usually a problem, but it often points to one.

The big no-no is entrained air. You might be tempted to call this “entrapped air,” but some industries differentiate these two terms. In cast concrete, for instance, entrainment is desirable; entrapment is not.

But I digress. We’ll call it entrained air. This stuff causes all sorts of problems: loud noise, reduced fluid viscosity, cavitation damage, lower thermal conductivity, and inefficient response times. Because gas is compressible and liquid is not, too much entrained air will make the system sluggish and “spongy.” The pump must work harder to compress the gas before it can compress the liquid.

Bottom line: Your hydraulic fluid shouldn’t look like beer on tap.

How Does Air Contaminate an RV’s Hydraulic Fluid?

How does air get in your system in the first place? Well, there are a few ways:

- All hydraulic fluid contains some dissolved air. Some hydraulic oils can contain up to 6-12% dissolved air by volume! Dissolved air can precipitate out of the solution as bubbles under agitation or low pressure (Henry’s Law).

- Some free air is naturally trapped when filling or flushing the system, or when replacing a component like a hose, valve, or actuator. Most, but not all, of this air is bled from the system after the initial purging cycles.

- Leaks in the system (e.g. loose threaded fittings) can allow air ingress.

- Low fluid levels in the reservoir will allow the pump will suck in air along with everything else, which heavily aerates the liquid. It’s like sucking a straw at the bottom of a milkshake. Vortexes can exacerbate this problem.

How to Bleed Air from an RV Hydraulic System

Free air is pretty easy to get rid of. You’ve probably “bled” your hydraulic system after a flush n’ fill procedure. Bleeding a hydraulic system is simply cycling the pressurized fluid through the system, dislodging any free air bubbles until they return to the reservoir where the air can be returned to the atmosphere from whence it came. This works pretty well except in really cold temperatures.

Entrained air is a little more difficult. It doesn’t always want to come out, especially if the hydraulic oil is cold and viscous. In the RV world, we recommend the caveman technique of wait-and-see. If you see foam in the reservoir, wait 10-30 minutes for as much air to either dissolve into or burp out of the fluid, then bleed the system again. Repeat this 3-4 times until, well, the pump sounds happy. The truth is that entrained air will dissolve and reappear with changes in fluid pressure, so it’s not necessarily a fixed amount. You’re just trying to keep it manageable.

Dissolved air … well, you’re kind of stuck with it. Fancy hydraulic systems have nifty gadgets like pressure vacuums and deareators to get rid of dissolved air, but that kind of thing doesn’t exist for RVs. Dissolved air causes problems when some of the air is “persuaded” to come out of solution and form bubbles, usually due to turbulent areas of low pressure around valves, restrictive fittings, and the pump itself. This is called gaseous cavitation, and it’s one reason why your hydraulic system might develop some problems over time.

Most of the time, however, RV hydraulic systems just aren’t used enough to develop these kinds of long-term problems. They usually suffer more from neglect than overuse.

Fun fact: The loud, whiny noise caused by air entrainment in a hydraulic system is actually caused by the shockwaves of tiny air bubbles imploding, usually from pump cavitation. Literally tons of tiny air grenades going off. Pretty cool, huh?

How to Fix a Loud Hydraulic Pump on an RV

So how do you fix your air entrainment problem? It’s actually pretty simple:

- Plug your RV into shore power if possible. At least make sure your batteries are in tip-top condition.

- Retract everything in the system. Double-check that the fluid level in the reservoir is at the maximum. If it isn’t, wait for the foam to dissipate for 15-30 minute, then fill to the maximum with the recommended hydraulic fluid (usually some kind of ATF). Check for leaks!

- Bleed the system. Consult your Owner’s Manual for directions. Wait 15-30 minutes between cycles. Don’t exceed the duty cycle of your pump, and don’t over-discharge your batteries!

- Ensure the breather cap is clean, or just replace it. A plugged breather cap can cause serious problems and induce lots of entrained air by causing a partial vacuum in the reservoir.

If you have a particularly nasty air bubble in your system (especially if you have single-acting cylinders), then there are other options for bleeding air out of the system … but I won’t go into those. They aren’t DIY-friendly, and with hydraulic fluid being pressurized up to 3,000 PSI, it’s not a skill you want to learn off the internet!

Leave a Reply