If you’ve been RVing for any length of time, someone has probably told you about the trick to “resetting” your propane tank:

- Turn off all propane-consuming appliances.

- Turn off the service valve on the propane tank.

- Wait 2-3 minutes.

- Slowly, slooooowly open the service valve.

- Continue life as normal.

Yes, this trick works. It’s just like the old IT joke: “Have you turned it on and off again?” But why does this work? What are you resetting? And will it happen again?

If you’re as curious as I am, you may enjoy this post. I’ve packed a lot of information into the following paragraphs. But speaking propane is its own language: tanks and cylinders, ACME threads, excess flow valves, inches of water column, flare fittings, vapor pressure, bleeder valves … you don’t need to know all this stuff to be a responsible RVer. But if you enjoy the little dopamine rush from learning something new, read on!

Propane: A Tale of Crude Oil

Propane is one of the many miraculous children of crude oil. When compressed, it becomes an energy-dense liquid, around 91,000 BTUs per gallon (at less than $2.50 a gallon!). In comparison, if you hooked up an ideal 100-Ah battery to a resistance heater, you’d get the equivalent of about 4,100 BTUs/hour before your battery died. Pretty measly compared to a gallon of propane.

That’s why RVs haven’t moved away from propane, you see. It just contains so much energy, chemical energy that can be easily converted into useful heat to cook your food, warm your air, and even cool your refrigerator.

Now, what we call “propane” is actually a combination of substances, namely propane, butane, and ethyl mercaptan. This gaseous slurry is called “LPG” for liquified petroleum gas. Ethyl mercaptan is added to give propane its characteristic rotten-egg odor (gross, but safe). In some parts of the United States, namely the South, butane may be added to propane to make “summer gas,” which is typically cheaper. But in the RV space, we’ve gotten in the lazy habit of using the terms propane, LP, and LPG interchangeably. Importantly, propane is NOT the same thing as natural gas, which is mostly methane.

To Propane, It’s Always Hot Outside!

Propane is stored as a compressed liquid but withdrawn as a vapor for service. Liquid stays in the tank; vapor travels through the pipes. To store LPG, RVs may use portable DOT propane cylinders or onboard ASME propane tanks. Towables generally use DOT cylinders; motorhomes use ASME tanks. The design of the two are overseen by different bodies: the Department of Transportation and the American Society of Mechanical Engineers, respectively.

But a tank is more than a fancy Tupperware container. Propane is highly volatile and flammable. In large amounts, it is an asphyxiant. It boils at -44 degrees at atmospheric pressure, which will cause frostbite on exposed skin within seconds. It must be stored under high pressure, sometimes above 300 psi! (for reference, a football is normally inflated to around 12 psi). So a tank, and all the valves connected to it, must control the storage and delivery of propane gas, and they must do it safely.

>>> READ MORE: Is Your Propane Tank Empty – Or Is It Just Too Darn Cold Outside?

What’s Inside Your Propane Tank Valve?

ASME tanks have separate valves and fittings for most of their functions. They also have a few extra valves for LPG evacuation, which is necessary for long-distance transport. But smaller DOT cylinders usually have a single integrated multivalve with all the main functions: OPD float, pressure relief valve, bleeder valve, and service connection.

Let’s narrow in on the service connection. That’s where the magic happens. When you twist open the triangular-shaped hand wheel of a modern OPD valve, you’re unseating a needle valve that allows gas to flow from the main tank reservoir. From there, where does it go?

Propane vapor is withdrawn through the vapor withdrawal valve, which has changed design in recent decades. If you’re old enough, you may remember the old-style POL fittings, named for their original maker: Prest-O-Lite. These bullnose brass fittings relied on metal-to-metal contact to make the fitting gas-tight. The POL fittings had lefthand threads that were started by hand to avoid cross-threading and then torqued to tight with a pair of wrenches.

Modern POL fittings may have a machined groove and a rubber O-ring in the mating faces to prevent leaks. These are called “soft-nose” fittings, and they are designed for connections that will be frequently disconnected, such as BBQ grills. Today, POL fittings are still popular in Australia, but they are being phased out here in the U.S.

POL Versus ACME QCC Threads

In 1998, the Department of Transportation mandated that all new propane tanks be built with Overfill Protection Device (OPD) valves per NFPA 98. OPD valves have a float “bobber” inside that shuts off the tank when 80% fill is reached. Today, OPD valves are required on all DOT propane cylinders 4-40# in size, and refill stores won’t refill your tank unless you have one.

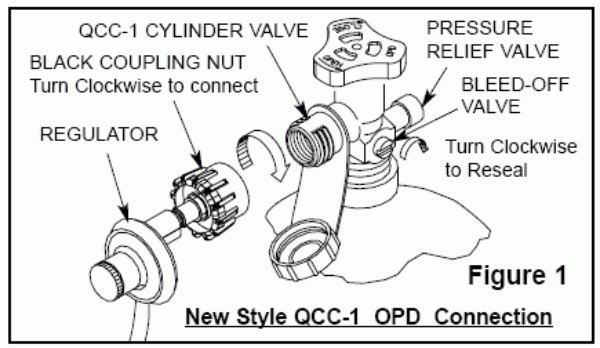

Typically, these OPD valves are paired with a nut-and-nipple QCC Type 1 fill fitting, which use external 1-5/16” ACME threads rather than the old POL internal threads (most multivalves still include the internal POL threads for backward compatibility, though). You don’t need a wrench to tighten these fittings. You just need to twist the big plastic nut in place until hand-tight. There is no need to crank the nut until your wrist hurts! Unlike NPT pipe threads, the ACME (no relation to the coyote) threads don’t keep the fitting gas-tight. There’s an O-ring on the discharge valve that seals the connection.

Modern OPD valves have a lot of advantages over POL valves. One of them is safety. With the old style, simply opening the service valve hand wheel would allow gas to escape. No longer! The QCC connectors have a built-in Discharge Check Valve. The propane tank will not open unless connected to a pigtail. See the little collar on the end of the pigtail fitting? That’s to depress the spring-loaded check valve so gas can flow.

>>> READ MORE: 7 Ways to Measure Your RV Propane Tank Levels

Meet the Culprit: The Excess Flow Valve

Finally, this train of inspection takes us to the star of our show: the excess flow valve. On a DOT cylinder, these valves are built into the QCC nut as part of the pigtail. On ACME tanks, they may be integrated into the hogtail or vapor withdrawal fitting.

An excess flow valve isn’t the exact same thing as a flow restriction valve or a check valve. A check valve, also called a backflow prevention valve, allows fluid to flow in one direction only. A flow restriction valve limits the maximum liquid flow rate, but it does not trigger a shutdown if the flow attempts to exceed that maximum. In comparison, excess flow valves close when the flow rate of vapor or liquid exceeds the valve’s rated flow capacity. Both QCC and POL fittings can be made with an excess flow valve.

But here’s the magic: Excess flow valves don’t shut off 100% of the flow. They leave a teeny-tiny little equalization hole open for gas to flow. It’s like Noah sending out a bird from the Ark: If the leak still exists, then the gas simply escapes. But if the leak has stopped, then the gas eventually builds up back pressure, which pushes back and releases the valve.

Again, these excess flow valves are integrated into the QCC Type 1 connector on a propane pigtail. The plastic nut on the pigtail is color coded to indicate flow capacities.

- BLACK are rated up to 100,000 BTU/hr

- GREEN are rated up to 200,000 BTU/hr (recommended for most RVs)

- RED are rated up to 400,000 BTU/hr

The pigtail should be sized based on the demands. If the excess flow valve capacity is too large, then it may not be triggered by a downstream leak or rupture.

How to Reset Your Excess Flow Valve on Your RV Propane Tank

Excess flow valves can be tripped by opening the tank too quickly (analogous to an inrush current for a motor). By slowly opening the tank, you’ll prevent these false positives. That’s why you’re supposed to slowly open the tank.

You can also trip an excess flow valve by opening the tank with a gas-burning appliance turned on. If your stove burner is open, for instance, then your gas piping will have approximately zero pressure. When you open the tank, gas rushes in to fill the void, but minimal backpressure is developed because gas continues to escape out of your burner. Your excess flow valve trips, and gas flow is reduced to a trickle.

This vapor trickle can be large enough to sustain one or two stove burners (usually 5,000-7,500 BTUs each). Often, the flames will be weak and have a yellowish tinge. But it’s not enough gas to sustain a hungry appliance like a furnace or tankless water heater.

But as I said, the fix is simple. Just turn everything off and on again. But occasionally, these excess flow valves inside the pigtails will fail. They can get stuck closed. Sometimes, a slight rap will dislodge the seated ball valve. If not, then you may need to replace the pigtail. Don’t buy the too-cheap-to-be-true imports on Amazon; buy something from a reputable supplier Marshall Excelsior or MB Sturgis.

Leave a Reply