You’ve probably heard the term “bad cooling unit.” This is a catch-all phrase to describe any number of failures with an absorption refrigerator’s cooling unit, which is the labyrinth of tubes partially encased in foam that we’ve been talking about. A failed cooling unit = a dead refrigerator. It runs, but no cooling.

A failed cooling unit will require major surgery to repair (or an entirely new refrigerator). Whether you operate the fridge on gas or electric doesn’t matter; the problem isn’t the heat source, it’s the rest of the refrigeration cycle. Be prepared to open your wallet!

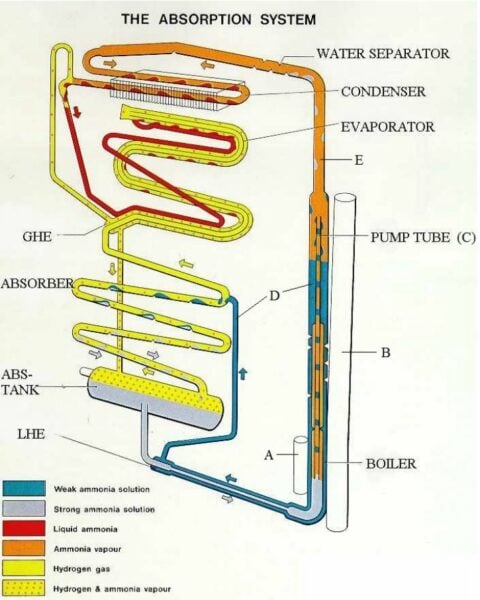

P.S. If you don’t really understand how heat makes cold, you can read my in-depth explanation of the RV absorption refrigerator. Or just the gentler introduction to the RV fridge if you’re not ready for all the chemistry.

What’s The Real Reason an RV Fridge Cooling Unit Fails?

Blockages

The most common cause of a failed cooling unit is a blockage. Blockages come in two types: temporary and permanent.

Temporary blockages in the tubing are usually from frozen water in the weak ammonia-water solution. Because ammonia lowers the freezing point of water, the solution won’t freeze at 32 degrees. But at some lower temperature, the weak ammonia solution will freeze, creating a sort of gel or a solid block. If allowed to thaw this blockage is reversible and generally harmless. This happens to your refrigerator all winter long while in storage. Norcold will tell you to stop running one of their refrigerators with a Cold Weather Kit once the temperature plummets to 0 degrees Fahrenheit. Without the Cold Weather Kit, 20 degrees is the recommended minimum limit.

If, however, you attempt to run your refrigerator with a frozen or partially frozen absorber, then you’ll likely starve the boiler of its ammonia-water solution. Temperatures will rocket. Sodium chromate will precipitate out of the strong solution and crystalize into rock-hard plugs. Sometimes, you can dislodge these crystallized plugs with a mallet or by turning your refrigerator upside down on its head. You’ll cross your fingers that the plug will migrate somewhere harmless. Sometimes this works for a day, sometimes a month, sometimes a year or more. Sometimes it doesn’t work at all. Either way, the answer is the same: Cooling units are not field-serviceable. The only permanent solution is replacement.

Pinholes and Cracks

Cracked tubing and pinhole leaks are a dire prognosis. It’s hard to stop a pinhole leak at 300+ psi, as you can imagine.

Why is the system pressurized? Well, ammonia boils at -28 degrees Fahrenheit at atmospheric pressure. That low boiling point makes it a great refrigerant, but there’s a catch. Imagine you’re a molecule of ammonia in the condenser, and you’ve just been cooled down to ambient air temperature – say, 75 degrees. To you, a little ammonia particle, that’s incredibly hot, so you’re going to vaporize immediately.

Well, we don’t want that. If ammonia doesn’t vaporize in the evaporator section (aka, your freezer), then it isn’t doing its job. We need to maintain the ammonia as a compressed liquid until we’re ready to let it do its thing.

Rather conveniently, it turns out that if we increase the pressure of a gas, we can increase its boiling temperature as well. The inverse is also true; lower pressure = lower boiling temperature. (That’s kind of the magic sauce of thermodynamics).

RV absorption refrigerators are pressurized to around 300-375 psi. If I check out my handy-dandy phase diagram for ammonia, I see that the saturation temperature of ammonia at ~300 psi is about 127 degrees Fahrenheit (the presence of other gases may affect this number, but I’m ignoring that for simplicity).

Turns out that 127 degrees Fahrenheit is a rather convenient number. It’s low enough to boil the ammonia with a heat source like a propane burner, but it’s high enough to condense the ammonia once it returns to ambient temperature – unless you’re camping in the Sahara desert where the air temperature is greater than 127 degrees, of course.

Unfortunately, this pressure creates significant forces. Even the tiniest pinhole in the tubing can allow hydrogen gas or ammonia vapor to escape. And these pinhole leaks often show up in the evaporator section (aka “catbox”), which is completely covered by block foam and wholly inaccessible. Even if you could find it, how easy do you think it is to repair a pinhole leak to survive 375 psi?

If the boiler fails (often from overheating), you can often find evidence of the leak as yellow powder around the base of the boiler. If the leak is recent, you’ll smell the ammonia leak, too.

Replacing an Absorption Refrigerator Cooling Unit

Hence why cooling units are not field-serviceable. If the cooling unit goes bad (leak or blockage), there is no fixing it. You’re either replacing the fridge or replacing the cooling unit – end of story. Entire companies are based on repairing and selling replacement cooling units, like ATCO America, JC Refrigeration, Cool-Fun, and Ozark – and they do brisk business! Cooling units commonly cost about $500-$1,200 plus shipping.

If you want to see exactly how a cooling unit is refurbished, check out this classic post from The RV Dcotor. The refurbished units must survive a pressurized leak test at 1,000 psi! When sourcing a replacement cooling unit, you can choose new or refurbished.

This isn’t a DIY project. You’ll need to remove and reinstall the refrigerator, remove and reinstall all the electronics, and properly seal the new cooling unit in place.

Leave a Reply