Hmmm … a torsion axle?

If you’re shopping for a small- to medium-weight trailer, you might have come across a torsion axle as mentioned in a sales brochure.

So you’re wondering: What’s the big deal with torsion axles? Are they better than a sprung axle? Why do some RVs have torsion axles and some don’t?

(Hint: Stay away from the forum posts! You’ll get preached at by both camps: People who love ‘em and people who hate ‘em, both biased by outlying personal experiences.)

I’ve worked extensively with both types of suspensions. And I’m not here to evangelize and convert you to one type of axle or the other.

Torsion axles have their strengths and weaknesses, just like leaf spring axles. If you’re curious about the pros and cons of a torsion axle, let’s look underneath!

How a Torsion Axle Works

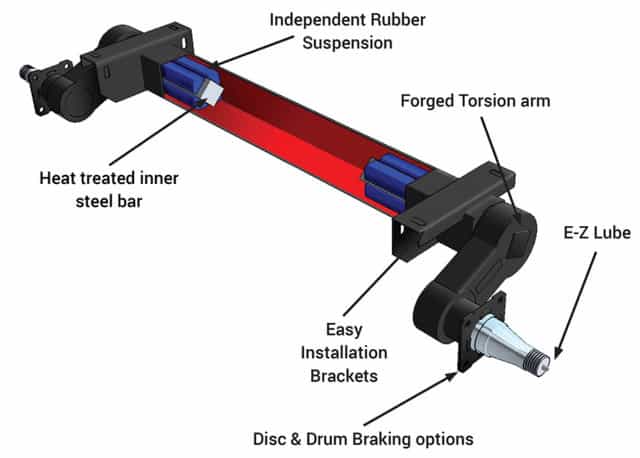

If you want to understand how a torsion axle works, you really need to see it in motion.

Here’s a product sales video showing how Torsion axles smooth out ride quality:

Advantages of a Torsion Axle

Smooth Ride

If you’ve already researched torsion axles, then you’ve likely heard this argument – but there’s a little more depth to it.

Yes, torsion axles provide a smooth ride with good shock absorption and damping. But the big difference is that torsion axles provide a smooth ride throughout a wide weight range – unlike leaf springs!

Leaf springs can provide a smooth ride, too – but only in a narrow weight range. You see, a 4,000-lb sprung axle with a 1,000-lb load will ride like a bucking bronco! The lighter the weight on a leaf spring, the stiffer the ride. The leaves just don’t compress enough to have any rebound.

Torsion axles aren’t like that. A torsion axle loaded to partial capacity still rides like a champ. That’s a big reason you see torsion axles on small trailers. If a small trailer weighs 3,000 lbs empty and 5,200 lbs at maximum, that’s a big weight range! You get much more consistent handling on smaller RVs with a torsion axle.

Independent Suspension

A torsion axle allows each wheel to move independently. If the right wheel hits a bump, only the right trailing arm jolts upward; the left side doesn’t move (doesn’t move much, anyway).

An independent suspension doesn’t matter much when towing on flat, straight roads. But when you’re traveling on potholed paths or easy 4WD roads, a torsion axle can significantly improve the side-to-side stability of a trailer. You get less “bump steer” and therefore much better tracking.

Here’s a video of torsion spring damping in action:

But with leaf springs, uneven roads make your trailer (and your heart) pretty jumpy!

Theoretically, the better handling and shock absorption of a torsion axle could increase the life of your camper, because less shock and vibration is being transmitted to the RV house, blah blah blah, but I’ve never witnessed any actual demonstration of this claim.

Superior Ground Clearance

Depending on how your torsion axle was designed, you *might* have more ground clearance than with comparable leaf springs.

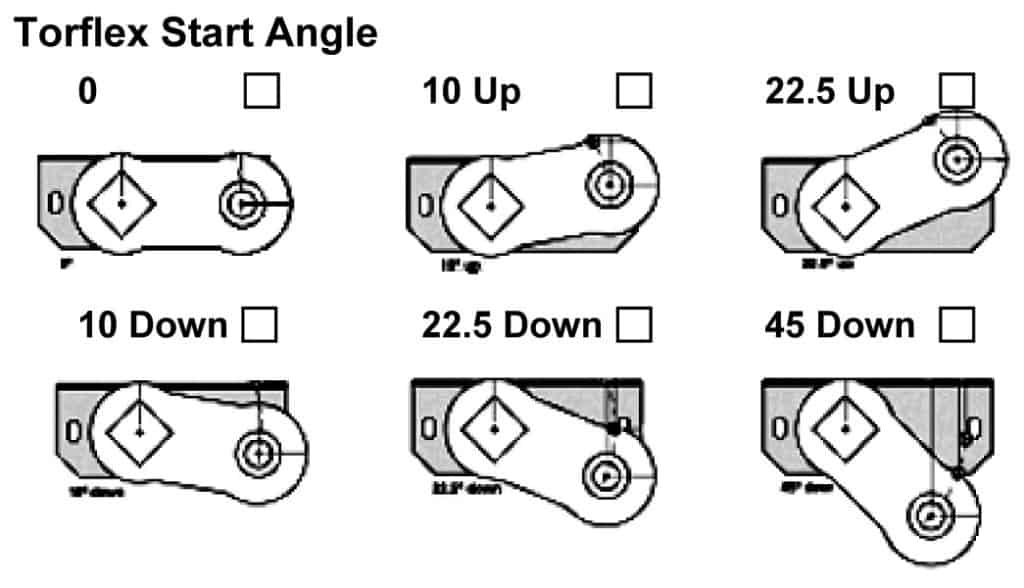

By adjusting the starting angle of the trailing arm (common 22.5 degrees up, 10 degrees up, 10 degrees down, 22.5 degrees down, or 45 degrees down), the designer can adjust the ride height and ground clearance of a torsion axle.

This is fixed once the axle is manufactured, though. It’s not something you can “adjust” in service. It’s part of the design itself.

For the same ride height, torsion axles with 22.5 and 45 degree down configurations typically have greater ground clearance than an analogous leaf spring axle.

That’s a good combination for better handling and better fuel efficiency without risking bottoming out or high centering.

Lower Ride Height

Ride height isn’t quite the same as ground clearance, so I gave it its own section.

- Ground clearance is the distance between the earth and the lowest component of your trailer (usually the axle).

- Ride height is usually the distance between the earth and the bottom of your trailer frame.

For the same ground clearance, torsion axles offer 2-4 inches lower ride height than an analogous leaf spring axle.

If you get a drop torsion axle, you can go even lower!

This design results in a lower center of gravity and improved handling on corners. Depending on your tow vehicle, it could also slightly improve fuel efficiency.

This is why torsion axles are highly recommended for horse trailers: A much smoother ride for the horses, and a much lower ride height for easier entry and exit.

Low Maintenance

Leaf spring suspensions have several parts: leaves, shackles, hangers, u-bolts, etc. These components need to be periodically painted and lubricated. Wearable parts, like bushings on equalizers and double-eye springs, will need to be replaced.

Torsion axles are built as inseparable assemblies. As far as you’re concerned, there are no parts that require periodic service. Just maintain your wheel bearings like usual!

Corrosion Resistant

This is a similar idea to “Low Maintenance,” but I think it deserves special consideration. Because the mechanical guts of a torsion axle are concealed within a hollow tube, these axles excel in marine and Rustbelt environments. That’s a big reason torsion axles are a favorite on boat trailers.

Structural Strength

Unlike leaf spring axles, torsion axles can be considered a structural cross member for the frame. Not that you care that much, but as a designer, that makes my job easier!

It’s also a warning to never replace a torsion axle with leaf springs without double-checking the frame design. You might need to weld in a new frame cross member!

Quiet Road Nose

No metal-on-metal contact with a torsion axle. No bushings to wear out and squeak. Torsion axles should be nearly silent.

Disadvantages of a Torsion Axle

Cannot Repair – Just Replace

The strength of a torsion axle is also its weakness. If it fails – if the cords wear out or separate, if the axle bends, if the trailing arms break – then you’ll be replacing the entire axle. Lock, stock, and barrel.

Hence why leaf springs remain popular with the expedition travel crowd. Leaf springs may be crude, but when something breaks in the bush, a leaf spring is a gazillion times easier to “redneck engineer.”

Note that replacing an axle isn’t that difficult – at least on paper. Most torsion axles are bolted to the trailer frame with four bolts. Unbolt, remove, rebolt new axle, done!

The challenge is getting the weight off the trailer in the first place. Which leads me to my next complaint …

Difficult to Jack Up

You shouldn’t jack up a torsion axle by the axle itself. You’re supposed to jack up a travel trailer or 5th wheel on a torsion axle suspension by the frame itself.

See the problem yet? A trailer frame is 16-24 inches off the ground. Unless you happen to have a 10-ton bottle jack or stack of 2×8 boards, your jack can’t reach the trailer frame!

Unless you’re a skilled DIYer with the right tools, it’s very difficult to replace a torsion axle yourself. However, you can take your camper to just about any truck n’ trailer service shop, and they’ll know what to do.

Cannot “Flip the Axle”

As I crowed about earlier, I love that, as a designer, I can play around with torsion axle starting axles, wheel sizes, drops/rises, and lift blocks to get the perfect combination of ride height and ground clearance.

But for you, the customer … well, you might just have to live with my choice.

You can’t adjust the starting angle of a torsion axle once it’s manufactured. The only thing you can do to adjust the height is add in a lift kit.

Compare that to leaf springs, where you can flip the axle from underslung to overslung, change the shackle lengths, add seat spacers, etc. Leaf spring suspensions are much easier to modify aftermarket.

Doesn’t Equalize Across Axles

Lack of equalization is arguably the biggest problem with tandem torsion axles.

There’s a reason you don’t see any torsion triple-axles and very few dual-axles. Torsion axles don’t like to share. Tandem-axle leaf spring suspensions with equalizers distribute the weight front-to-back, not just side-to-side. Tandem torsion axles don’t.

In real life, this shows up in two places:

- When your trailer isn’t being towed level, one of your axles will be carrying more weight than it should! Not good!

- If you drive over a big bump, each axle might be momentarily overloaded. For more information on this potential problem, you can read this engineering analysis at Mechanical Elements.

For these two reasons, most designers avoid triple-axle torsion axles. There’s just too much at risk.

Some designers do choose to use double torsion axles, but generally, each axle is somewhat “oversized” as a safety factor.

You can learn more about the pros and cons of dual-axle RVs here!

Torsion Axles FAQs

Who Makes Torsion Axles?

The two big manufacturers are Dexter and Lippert. Dexter controls most of the market. Another OEM is Flexiride, but they’re better known for their torsion half axles.

- Dexter

- Lippert

- Flexiride

Which RV Manufacturers Use Torsion Axles?

Below is a non-exhaustive list of some of the major RV brands that use torsion axles.

- Rockwood

- Airstream

- Flagstaff

- R-Pod

- Jayco

- Winnebago

- Escape Trailer

- Lance

Torsion axles are also the design of choice for most mini travel trailers from manufacturers like NuCamp, NoBo, Casita, etc.

You’ll also find torsion axles underneath most teardrop trailers.

Why Do RV Manufacturers Use Leaf Springs Instead of Torsion Axles?

- Leaf spring suspensions cost less (of course).

- Leaf spring suspensions equalize in tandem- and triple-axle applications. Torsion axles don’t. (See Disadvantages).

How Long Do Torsion Axles Last?

Want to know how long torsion axles last?

Assuming you don’t bend the axle in an accident … 10-15 years, on average. Some people get 20 or more.

The rubber cords will eventually break down, which will decrease your ride height and ground clearance. You’ll notice more sloppy handling, too.

Worst case scenario: Eventually, the trailing arms will “bottom out” on bumps, which means the axle should be immediately replaced. If the suspension bottoms out, it’s transferring all the shock to the rigid frame – not good!

What’s Torsion Axle Camber?

You might have peeked underneath your RV and seen that your torsion axle has a bend in the middle. If you’re worried that you’ve accidentally damaged your axle, don’t be!

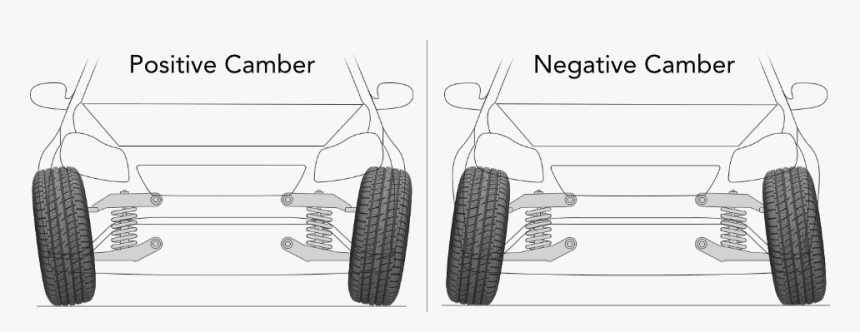

All torsion axles are built with camber. In other words, the axles aren’t straight – they are intentionally bent upward during the manufacturing process.

When your trailer is fully loaded, the weight of the camper will force the axle to unbend and become straight again. Nifty, huh?

Camber is important because it properly aligns your tires.

- Too much camber (positive camber), and you’ll wear the outside of your tires.

- Too little camber (negative camber), and you’ll wear the inside of your tires.

Tires heavily worn on the inside is a classic sign of negative camber – which usually means an overloaded trailer!

You can learn more about diagnosing worn tires at my FAQ guide here.

How Much Space Should a Torsion Axle Have for Bump Clearance?

There should be about 2.5-4.0 inches between the top of your tire and the wheel well. This prevents your tire from hitting the wheel well, and it prevents rocks and debris from getting stuck in narrow spaces.

As an axle ages, it will tend to sag. This will reduce its bump clearance. Every few months, check the clearance between your wheel well and tire. If you can fit your fist between the two, you’re probably good to go.

Should You Buy an RV With a Torsion Axle?

So, how important are torsion axles?

If you’re shopping for a new RV, and you’re not a serious off-roader, I certainly wouldn’t discard your favorite because it doesn’t have a torsion axle. There are hundreds of thousands of RVs, trailers, and trucks on the road with leaf spring suspensions. They do alright. And if you want a better ride quality, you can always add shocks!

With that said, I do believe the pros of a torsion axle usually outweigh the cons.

For small campers (below 5,000 lbs curb weight), I definitely prefer torsion axles. The ride quality and superior handling win me over every time!

For larger campers (and anything with double axles), I’d instead favor equalized sprung axles with shocks. I wouldn’t say no to double torsion axles, though.

Leave a Reply