Until now, I’ve aimed most of my words about RV roofing at the winner by popular choice: membrane roofing. It’s what most people call “rubber roofing.” The two most popular membrane roofing types are EPDM and TPO, with PVC taking the bronze. Dicor and Alpha Systems are the two largest OEMs, I think.

But there is a fourth option (and a fifth, too, but we won’t worry about it yet). The fourth option is fiberglass, and it’s unofficially accepted as the best RV roofing material.

What Is an RV Fiberglass Roof Made From?

All the membrane roofs, you see, are simply large plastic sheets, rather like fancy tarps. They are generally soft and flexible, which allows them to wrap around the compound curves of modern RV roofs, but that same softness also makes them vulnerable to tree limbs, hail, rocks, and even the hard urethane soles of shoes.

Fiberglass, meanwhile, is a hard composite material. What we call a “fiberglass” roof is actually a matrix of fiberglass fibers (or a weave) mixed with a cured polymer resin, but we use “fiberglass” as a shorthand description. A more technical description is Glass-Reinforced Plastic (GRP) or fiberglass-reinforced plastic (FRP). In the RV industry, roll fiberglass is often referred to by its eponymous trade name, Filon, which is manufactured by Crane Composites.

When cured, the composite material is extremely strong yet lightweight. It can be dyed different colors and made in different thicknesses. The raw fiberglass is coated with a gelcoat, which is a clear varnish that both beautifies and protects the base layer from scratches and UV damage. Fiberglass is quite strong, but brittle; it tends to break rather than bend.

Fiberglass can be manufactured in almost any shape: plate, sheet, roll, rod, pipe, and just about any other shape you can imagine. It can be molded, extruded, pultruded, and sprayed. It’s used in everything from skis to boat hulls to swimming pools. I’ll save the rest of the materials science lecture, but it’s truly one of the proteges of crude oil and modern science. You come across fiberglass all the time in real life: bathtubs, surfboards, shower wall panels, and even septic tanks.

What Are the Different Types of RV Fiberglass Roofs?

The phrase “fiberglass roof” can also apply three different kinds of RV fiberglass roofs:

- A loose-laid fiberglass skin, where a layer of FRP is bonded to a substrate and loose-laid over the RV roof decking.

- A laminated fiberglass deck, where a layer of thin fiberglass is bonded to a composite sandwich panel. This is very similar (sometimes identical) construction to a laminated sidewall.

- A molded fiberglass roof, where a thick layer of fiberglass is sprayed or molded into its final, permanent shape.

- A formed fiberglass roof, where a rigid fiberglass roof cap is assembled from one or more pieces, similar to the front cap of a modern toy hauler.

>>> READ MORE: RV Fiberglass Delamination: What To Do When the Worst Happens to You!

Loose-Laid Fiberglass Skin

A loose-laid fiberglass skin is where a layer of thin fiberglass with substrate is loose-laid over the RV roof decking, which is supported by trusses. Typically, this substrate is either luan plywood, Azdel, or another thin composite (usually less than ⅛” thick). The fiberglass and substrate layers form a “skin,” which is unrolled off a giant coil at the factory and laid over the roof. Think saran wrap over Tupperware. The skin is secured at the edges by staples or screws (with the help of aluminum trim) and secured in the field by the roof components.

Here is an example from NuCamp of a loose-laid fiberglass skin:

Laminated Fiberglass Deck

A laminated fiberglass deck is where a layer of thin fiberglass with substrate is bonded to a composite sandwich panel. As I said, this is very similar to a laminated sidewall: it fuses into a cohesive whole. The core is usually foam, the inside skin is the ceiling panels; the outside skin is the roofing fiberglass. Usually, the core is bolstered by a semi-structural frame made out of aluminum.

>>> READ MORE: The Ultimate Guide to RV Sidewall Construction Types

Here is an example of a laminated fiberglass roof from Ember RV:

Molded Fiberglass Roof

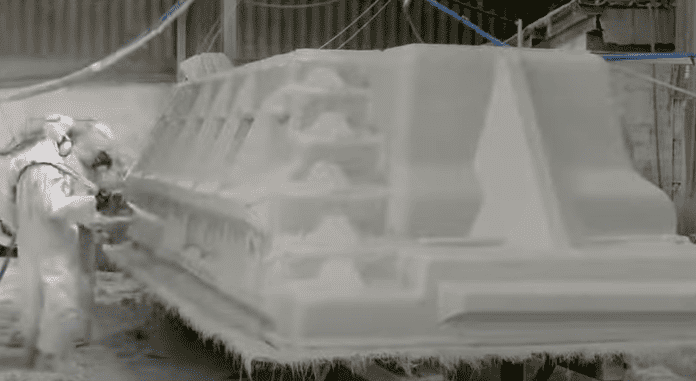

A molded fiberglass roof is where a thick layer of fiberglass is sprayed or molded into its final, permanent shape. This is how classic “egg” campers like Scamps, Casitas, and Olivers are made. Unlike the first two methods, a molded fiberglass roof results a very thick, solid fiberglass shape, anywhere from ⅛” to ⅜” thick. If you want a design a continuous, structural, compound-curved roof, then molded fiberglass is one of your best choices!

Here is an example of a molded fiberglass camper from Escape Trailers:

Formed Fiberglass Roof

Technically, ths is a type of molded fiberglass roof, but unlike a “fiberglass trailer,” the fiberglass isn’t structural. The formed roof is made of one or more formed fiberglass pieces, usually open-molded. These roof pieces are then installed on the roof, rather like interlocking jigsaw puzzle pieces. (Think of the fiberglass front cap on many modern 5th wheels, toy haulers, and luxury travel trailers).

The 2-piece version is a rather rare type of roof that has fallen out of favor due to the potential water leaks at the joints. The seamless 1-piece version is still out there, but it’s expensive.

Here is an example of a formed fiberglass roof from DRV Suites:

Benefits of a Fiberglass Roof

- Seamless (usually): Although some antiquated fiberglass roofs are two-piece, most modern fiberglass roofs are seamless and continuous.

- Puncture-resistant: GRP is rigid and hard. It takes a strong, angry tree limb to puncture through fiberglass!

- Easy maintenance: Fiberglass resists most oils, solvents, mildew, and grime. It’s hard to stain and easy to clean.

- Sound absorption: Fiberglass doesn’t cause the “ping-ping-ping” sound of hail that is notorious to an aluminum roof.

- Less risk of delamination: While fiberglass roofs can delaminate, they aren’t as likely to separate as a rubber RV roof, which are more sensitive to wind- and water-damage.

- Low thermal conductivity: Take this benefit with a grain of salt. Yes, fiberglass has a much lower thermal conductivity compared to, say, aluminum, but the R-value of any material is based in part on its thickness. Most RV fiberglass roofs are too thin to add any significant thermal insulation. A clean fiberglass roof, however, can help reflect solar radiation and decrease heat gain.

Downsides to a Fiberglass Roof

- Weight: FRP is heavy! And premium fiberglass is usually thicker and therefore heavier. For reference, 0.060” Filon G3 fiberglass material is 0.41 lbs/sqft. Alpha Systems Superflex 0.030” EPDM, a popular “rubber” RV roofing membrane, is only 0.162 lbs/sqft. To be honest, however, I wouldn’t worry about the weight difference much. At most, the difference is 100-300 lbs., even on the largest motorhomes.

- Cost: Yes, fiberglass costs more. But again, to be honest, I wouldn’t be overly concerned about this. The final cost of your RV will be decided by a 100 factors more important.

- Ease of repair: Fiberglass be temporarily patched with RV roof repair tape, but a full repair requires someone who knows autobody repair (e.g. Bondo + paint).

- Impact resistance: Fiberglass can be damaged by point loads and shock impact like hail and stones. Spiderweb cracking, in particular, can be difficult to fix.

So is a fiberglass roof better than any other? Eh … I wouldn’t say that. Fiberglass comes in grades and thicknesses, just like any other material. Is a 0.030” fiberglass roof roof better than a 0.045” PVC roof? I wouldn’t be so sure of that.

Ceteris paribus, yes, I think fiberglass is a superior roofing material than rubber membranes like TPO and EPDM – but the quality of installation matters more than the quality of the materials.

Leave a Reply